This avancon ZPC belt conveyor concept is externally and functionally identical to the avancon ZPC roller conveyor concept. Externally, there is no difference from the outside.

It also only works in zones. Of course the belt is completely different from the rollers.

The avancon ZPC Belt Conveyor is simple, simpler than any existing belt conveyor.

Have you ever replaced a belt, a gear motor or a drum motor of a 5 or 10 m long conventional belt conveyor?

- It took hours!!!

This avancon ZPC Belt Conveyor is a fantastically engineered and patent pending concept that offers the easiest maintenance of any conveyor.

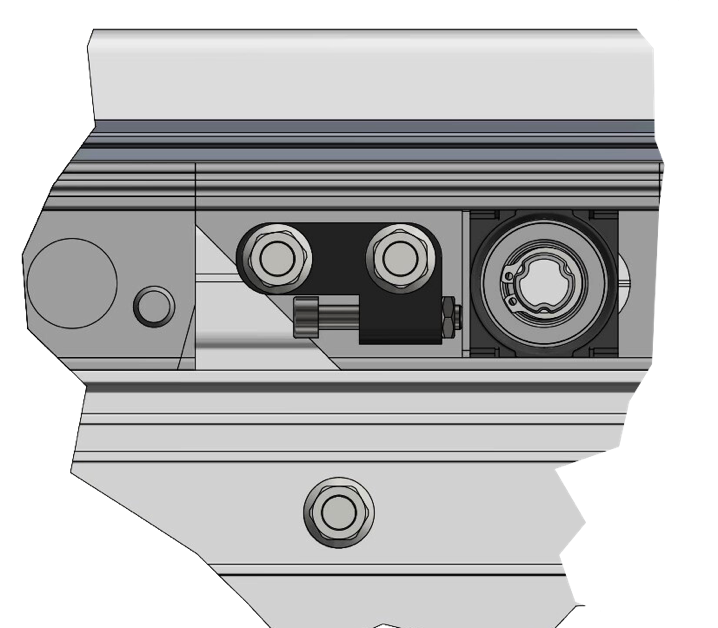

Open the outer profile with 4 screws - remove one of the zone belts along with the BLDC Flat Gear Motor. Then insert a new belt and close the profile again. That’s it.

Can you imagine how long it takes? - Only a few minutes!

The only thing left to do is to connect the cables to the control boxes in the main profile. Otherwise,, there is nothing to fix or to assemble.

To replace a defective zone belt, simply bend the chassis end part down and you can remove the belt.

Insert the new belt in the reverse way.

Then tighten the belt by bending he chassis end part back up.

You still have the possibility to fine tune the belt tension so that the belt is always centered.

We propose to do this as soon as the belt is tensioned.

In addition to the automagical tensioning of the belt by moving the chassis end up, we have also installed belt-tensioning possibilities on both sides. This allows you to correct the belt-running in the middle. You may just tighten a screw or loosen the screw slightly.

We suppose to let the belts run before for 30 minutes or so.

For all

goods with flat

bottom use only

avancon Roller Conveyors

with polyurethane

tires instead

of Belt

Conveyors