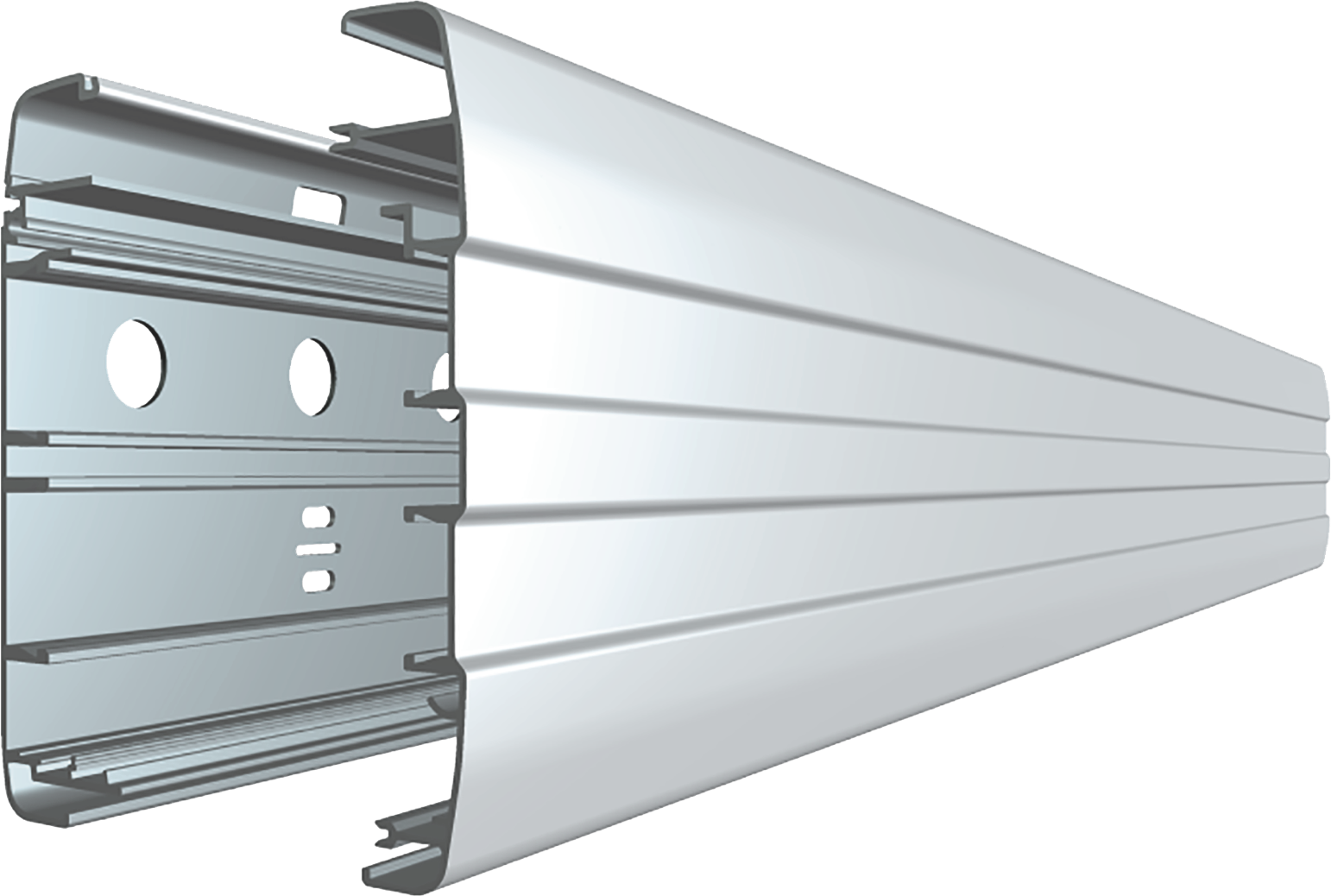

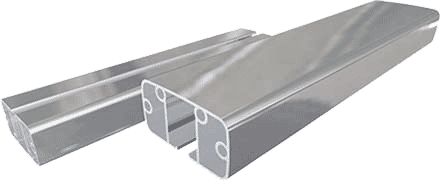

Aluminum is now the second most widely used metal in the world, after iron. This is because Aluminum has a unique combination of attractive properties. Low weight (about 1/3 of steel; even when constructed with thicker walls it is mostly only 50% of steel), high strength, superior malleability, easy machining, excellent corrosion resistance and good thermal and electrical conductivity are amongst Aluminum’s most important properties.

Anodizing increases the thickness of the oxide layer and thus improves the strength of the natural corrosion protection.

In addition, it creates a fine silk-like mat surface and confers a dynamic line design.

Since 1909 airplanes have been made of Aluminum. Now, also the car industry has discovered this material. Also. most Computers and other products from Apple are made of anodized Aluminum.